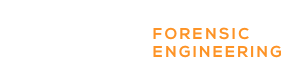

We use a failure analysis process based on years of experience investigating losses, both large and small, that begins with understanding the mode of failure and then expands to probe the role of environment, conditions, or a combination of factors that led to failure. Our approach ensures the subsequent analysis of the system – including the design, installation, maintenance, manufacturing, and operation of components – is unbiased and leads to actionable conclusions for our clients

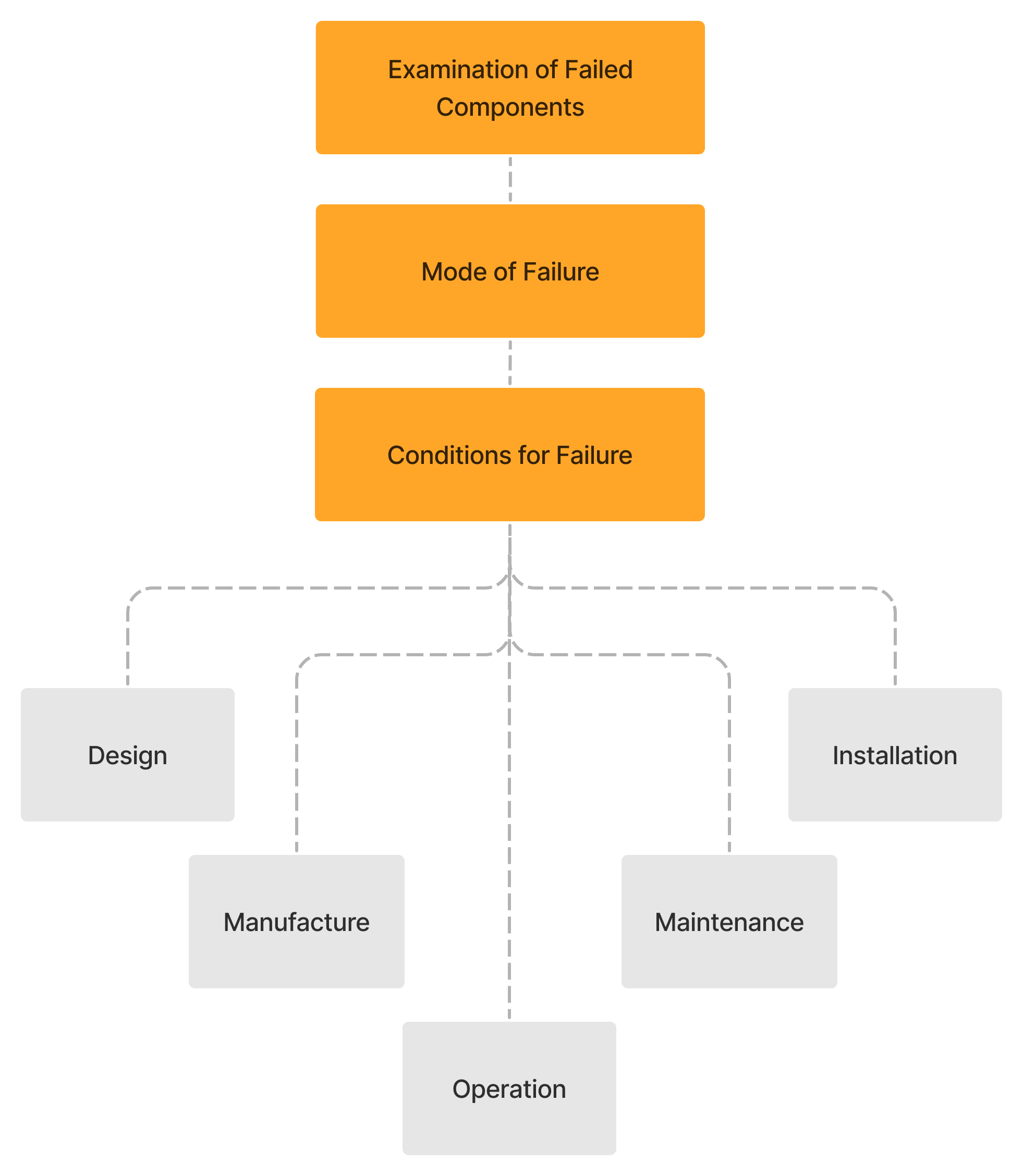

Mechanical failures can involve component failures, equipment failures, or entire system failures like high-rise plumbing systems.

Whether it is a component or a system investigation, the failure analysis begins at the specific failure point(s) and expands out to involve the system and operating conditions. Therefore, most of the detailed mechanical failures will have an aspect of materials engineering/fractography to get started on the investigation path. At Oak, we have both mechanical and materials expertise in-house and can work fluidly between these two disciplines to move the investigation forward in the appropriate manner.

Examples include:

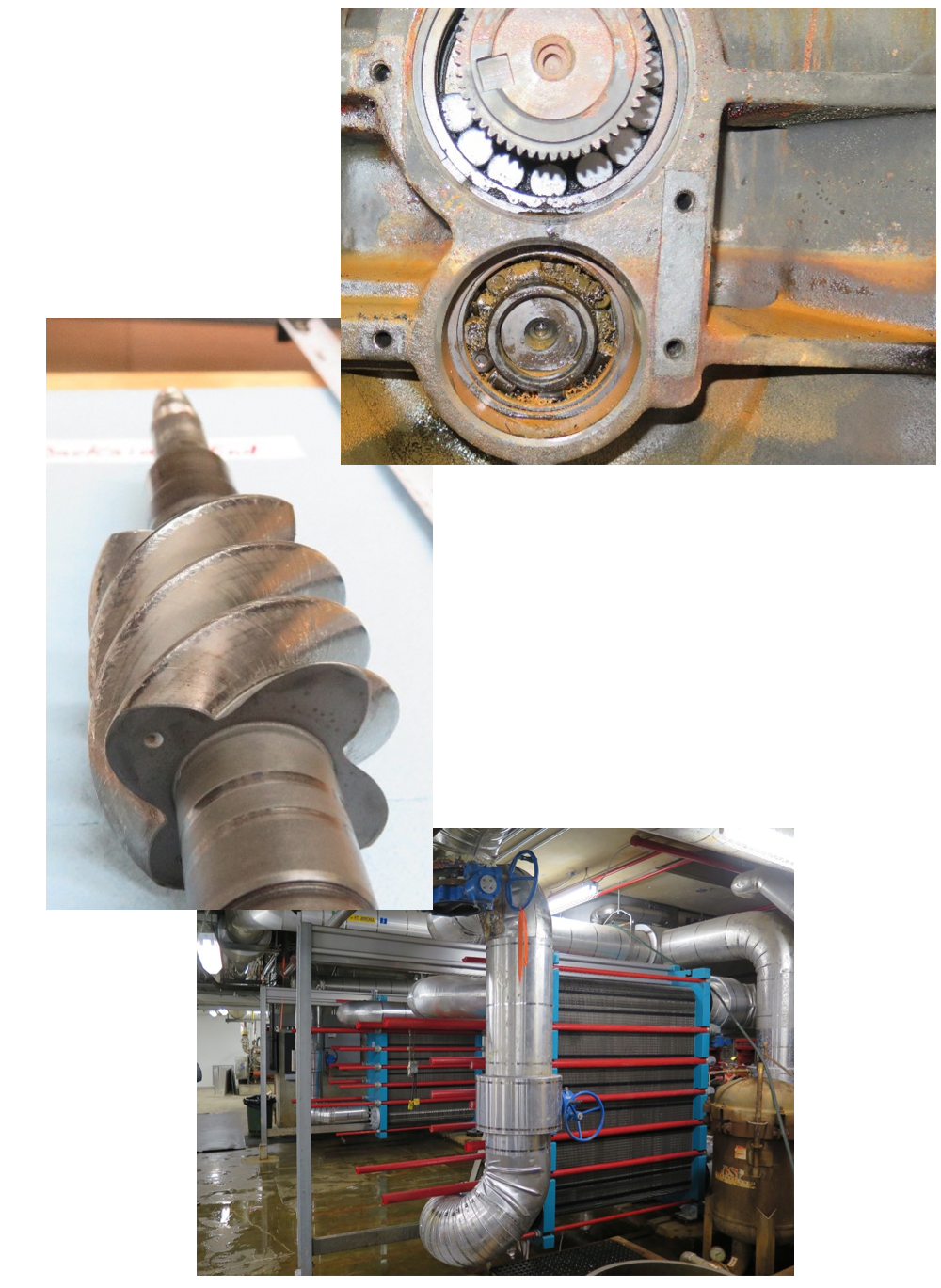

Many losses are precipitated by the failure of a piece of a component. Metallurgical / Material failure analysis is a valuable tool that assists in identifying the mode of failure, otherwise known as the “fingerprint”. This could be fatigue, brittle fracture, ductile overload, corrosion, etc. Oak’s personnel have expertise in performing failure analysis of metals, plastics, and composites.

Examples include:

Structures can be built from a variety of different materials. Steel, wood, concrete, aluminum, and composites are most common, but under load, knowing how each of these materials behaves and interacts with each other is at the root of each of our structural investigations.

Examples include:

Heavy equipment is used in construction, oilfield, forestry, and mining. Regardless of the industry sector, all heavy equipment shares common engineered components such as steel-frame construction, motors, transmissions, gearboxes, hydraulics, pneumatics, wire ropes, and electronic controls, just to name the most common. By understanding how these components work together, Oak can approach any heavy equipment failure confidently.

Examples include:

When losses get large (into the $1 Million+ range of quantum) or injuries occur, the causation investigations can often involve more than one discipline of expertise, which means that the client must either hire a large firm which may or may not have all the appropriate experts or several specific independent experts.

Irrespective of which method is used, having several experts investigating a loss can lead to data overload and confusion since they all have their own analyses to complete.

Oak’s personnel have the experience to lead these investigations and act as “point-person” for which all the specific technical experts run through. This results in a smoother, more cohesive experience to answer questions posed by the client, as well as a clear, concise report for the client. This process can also result in lower overall investigation costs, and it reduces much of the confusion and headaches of managing multiple experts on a loss.

1143 42nd Ave SE

Calgary Alberta T2G 1Z3

Please fill out the form and we will get back to you.